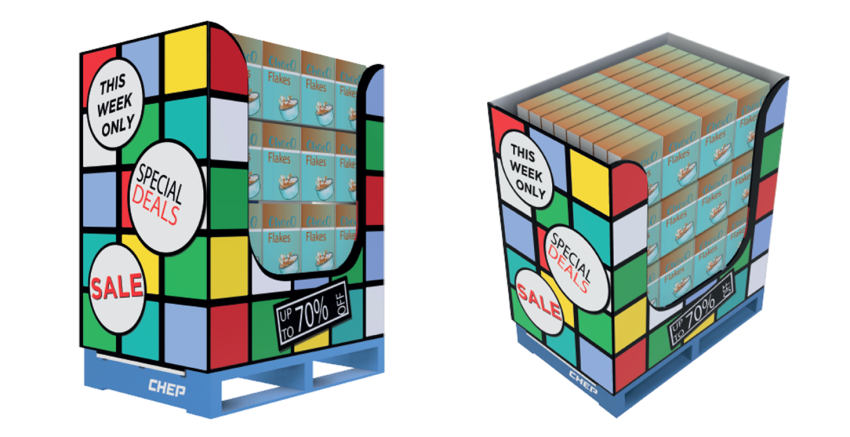

Retail-ready packaging offered by the supply chain company reduces the number of touchpoints, minimise time and allows for innovative branding and seamless shelf integration

JOHANNESBURG – Innovative retail platforms recently launched in stores have emerged as a hygienic sales solution during the safety-conscious pandemic era, while also sustainably providing choice and convenience for South African shoppers.

Retail-ready packaging (RRP) is a supply-chain innovation that allows products to be moved from factory floor to the store floor on a single pallet that has been thoughtfully designed to be delivered either directly within a shelf, in an aisle, or as a freestanding unit.

Since the lockdown, RRP has come into its own as a retail safety solution that provides enhanced hygiene for staff and shoppers alike. The packaging reduces the number of product touchpoints at warehouses, distribution centres and in stores.

CHEP, the supply chain solutions company, provides two RRP solutions, a 900x600 wooden platform and a 600x400 plastic platform. Both allow for innovative branding and seamless shelf integration.

A client sourced, protective cardboard wrapping doubles up as a branding and marketing opportunity in the store. Once the unit is in place, a shop assistant simply tears away the perforated section of the unit to display the products. The solution includes shelf-ready display units for certain stock-keeping units (SKU’s) to make the refill of shelves easy, safe and quick.

The new units minimise replenishment time and merchandising activities for optimal safety. Stock can arrive pre-filled on a CHEP retail pallet. This makes it easy to handle by store staff, or to roll into position using a pallet trolley, with little need for manual work, staff handovers or touching of surfaces. RRP also allows the shopkeeper to move product and displays to different high traffic zones through the day, without having to unpack shelves.

In addition to the safety aspects, retail-ready packaging minimises packing time, and eliminates the need for most secondary packaging, which saves on resources and avoids waste – helping to create a greener supply chain.

“We are pleased to be able to offer our RRP solutions at a time when retailers and customers are looking for life’s essentials with optimal social distancing,” said CHEP South Africa’s In-store Solutions Manager, Conor Powell. “RRP address these needs, while also minimising financial loss through stock breakages, damages and theft as products are transported from their source to the shop floor.” In a survey of its international clients, CHEP found that a major retailer cut replenishment time by 75-80% and boosted sales by 7-8% after adopting retail-ready display platforms.

Mac Mabidilala, Head of Research, Trade Intelligence added, “Retail-Ready Packaging is one of the evolving retail trends we are seeing in 2021 and is poised to accelerate. The growth in convenience stores with their basic layouts and typically lower staffing resources are among the reasons behind the increasing demand for retail-ready packaging. From a supplier perspective, retail-ready packaging is a great way to maintain prominent shelf presence and branding in store formats that are difficult to merchandise, or where merchandising opportunities are not available”.

All CHEP RRP platforms form part of the company’s circular-economy, share-and-reuse model. The business model has seen CHEP rated the second most sustainable company in the world in the 2021 Dow Jones Barron’s sustainability rankings.

“These platforms ensure greater efficiencies and minimise waste, for greater sustainability,” said Powell. “Neuroscience research also indicates that the platforms encourage impulse purchases by consumers and the fewer touchpoints of the end-to-end journey meet the new hygiene needs of today’s shopper.”

In South Africa, the CHEP RRP In-store Solutions were successfully launched with known-value items such as sugar, Powell explained. Smaller 400x600 display pallets can also be deployed in aisles for categories such as snack foods, personal care and home care.

“These products move quickly and are more likely to face material impacts through damage or slower replenishment,” he said. “We were excited that our new solutions have been positively received by shoppers and retailers. We are confident that demand will only increase in these safety- and sustainability-conscious times.”

About CHEP

CHEP helps move more goods to more people, in more places than any other organisation on earth. Its pallets, crates and containers form the invisible backbone of the global supply chain and the world’s biggest brands trust CHEP to help them transport their goods more efficiently, sustainably and safely. As pioneers of the sharing economy, CHEP created one of the world's most sustainable logistics businesses through the share and reuse of its platforms under a model known as ‘pooling’. CHEP primarily serves the fast-moving consumer goods (e.g. dry food, grocery, and health and personal care), fresh produce, beverage, retail and general manufacturing industries. CHEP employs approximately 11,000 people and believes in the power of collective intelligence through diversity, inclusion and teamwork. CHEP owns approximately 330 million pallets, crates and containers through a network of more than 750 service centres, supporting more than 500,000 customer touch-points for global brands such as Procter & Gamble, Sysco and Nestlé. CHEP is part of the Brambles Group and operates in approximately 60 countries with its largest operations in North America and Western Europe. For more information on CHEP, visit http://www.chep.com. For information on the Brambles Group, visit www.brambles.com.

Brambles Limited (ASX: BXB): Under the CHEP brand Brambles helps move more goods to more people, in more places than any other organisation on earth. Its pallets, crates and containers form the invisible backbone of the global supply chain and the world’s biggest brands trust Brambles to help them transport their goods more efficiently, sustainably and safely. As pioneers of the sharing economy, Brambles created one of the world's most sustainable logistics businesses through the share and reuse of its platforms under a model known as ‘pooling’. Brambles primarily serves the fast-moving consumer goods (e.g. dry food, grocery, and health and personal care), fresh produce, beverage, retail and general manufacturing industries. The Group employs approximately 12,000 people and owns approximately 330 million pallets, crates and containers through a network of more than 750 service centres. Brambles operates in approximately 60 countries with its largest operations in North America and Western Europe. For further information, please visit www.brambles.com

For more information, please contact:

Victor Collado

Director, Corporate Communications

Europe, Africa, India and Middle East

Brambles Group

victor.collado@brambles.com

www.brambes.com

Michelle Ramkalawan

Team Leader, Digital and External Communications

Africa, India, Turkey and Middle East

CHEP | Brambles Group

michelle.ramkalawan@chep.com

www.chep.com